Introduction: In the ever-evolving world of commerce, packaging plays a pivotal role in capturing consumer attention, conveying brand identity, and ensuring product safety. As a China-based Custom Packaging Box Manufacturer, understanding the intricacies of custom packaging is crucial to stand out in the market. This comprehensive guide explores the key considerations for creating effective Custom Packaging Boxes, from classification and design to production and important guidelines.

Classification of Custom Packaging: Custom packaging can be classified into several categories based on its purpose, material, and style:

a. Product-Specific Packaging: Tailored to fit the unique dimensions and requirements of a specific product, ensuring optimal protection and presentation.

b. Retail Packaging: Designed to enhance shelf appeal and brand recognition in a retail environment, often including eye-catching graphics and branding elements.

c. E-commerce Packaging: Geared towards durability and convenience for shipping, with a focus on minimizing damage during transit and providing a memorable unboxing experience.

d. Luxury Packaging: Exudes premium aesthetics and sophistication, incorporating high-end materials, finishes, and intricate designs.

e. Eco-Friendly Packaging: Reflects a commitment to sustainability, utilizing recyclable, biodegradable, or compostable materials to minimize environmental impact.

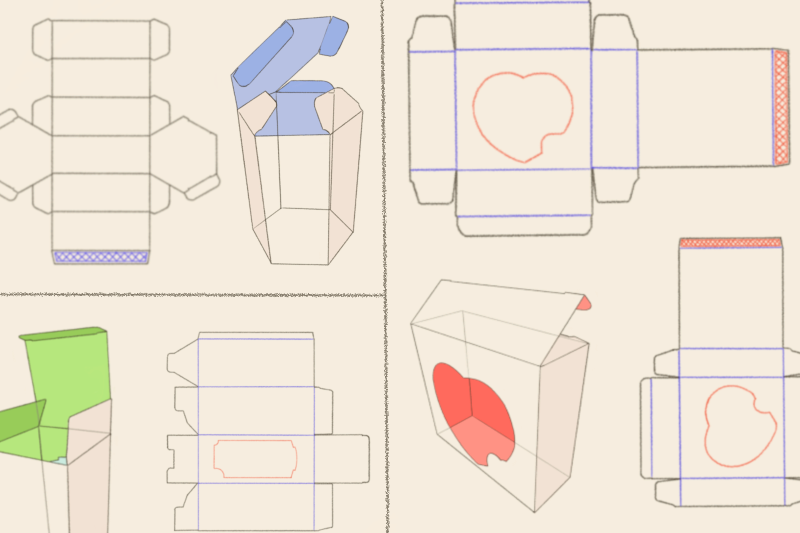

Steps in Custom Packaging: Creating effective custom packaging involves a series of carefully orchestrated steps:

a. Research and Planning: Understand your target audience, product requirements, and market trends to align your packaging strategy with consumer preferences.

b. Conceptualization: Develop initial design concepts that encapsulate your brand’s essence and resonate with your audience.

c. Structural Design: Create the packaging’s physical structure, considering factors like size, shape, functionality, and materials.

d. Graphic Design: Incorporate branding elements, visuals, and messaging to convey your brand story and enhance visual appeal.

e. Prototyping: Produce prototypes to evaluate the packaging’s functionality, aesthetics, and durability before proceeding to mass production.

f. Testing and Iteration: Conduct testing to ensure your packaging meets quality standards and make necessary adjustments based on feedback.

g. Finalization: Once satisfied, finalize the design and materials for production.

Cylinder Box with Gold Foil Stamping and Spot UV

This new cylindrical packaging box has the brand logo engraved on the surface by gold foil stamping process and covered with spot UV. This is a brand new design with significant upgraded packaging. The inner tray is wrapped with premium foam for better protection.

Custom Packaging Design: An effective custom packaging design goes beyond aesthetics, capturing the essence of your brand and product. Consider these aspects:

a. Brand Identity: Ensure your packaging aligns with your brand’s values, colors, and logo, fostering immediate recognition.

b. Visual Hierarchy: Use design elements to guide the consumer’s gaze, emphasizing key information such as product name, features, and benefits.

c. Typography: Choose legible fonts that reflect your brand’s personality and complement the overall design.

d. Colors and Finishes: Select a color palette that resonates with your target audience, and consider finishes like matte, gloss, or embossing to enhance tactile appeal.

e. Imagery: Integrate high-quality product images and illustrations that showcase your offering from different angles.

f. Sustainability: Incorporate eco-friendly design elements to communicate your brand’s commitment to environmental responsibility.

Packaging Box Production Process: The production of custom packaging boxes involves multiple stages, each contributing to the final product’s quality and appeal:

a. Material Selection: Choose appropriate materials based on factors such as product type, protection requirements, and sustainability goals.

b. Printing: Apply chosen designs to the packaging material using techniques like offset printing, digital printing, or screen printing.

c. Cutting and Creasing: Precision cutting and creasing machines create the packaging’s desired shape and structure.

d. Folding and Gluing: Assemble the packaging using automated folding and gluing equipment to ensure uniformity and durability.

e. Quality Control: Rigorous inspections at various production stages help identify and rectify any defects or imperfections.

f. Finishing Touches: Apply additional finishes, such as embossing, debossing, varnishes, or laminates, to enhance the packaging’s visual and tactile appeal.

Considerations for Custom Packaging: Creating successful custom packaging goes beyond aesthetics. Keep these important guidelines in mind:

a. Functionality: Prioritize the packaging’s ability to protect the product during storage and transportation while offering easy access to the contents.

b. Unboxing Experience: Craft an unforgettable unboxing experience that delights and surprises customers, leaving a lasting impression.

c. Regulatory Compliance: Ensure your packaging adheres to local and international regulations regarding safety, labeling, and environmental standards.

d. Sustainability: Embrace eco-friendly materials and practices to reduce your carbon footprint and appeal to environmentally conscious consumers.

e. Cost-Efficiency: Strive for a balance between quality and cost-effectiveness to maximize your packaging’s value without compromising your budget.

f. Adaptability: Design packaging that can accommodate potential changes in product dimensions or branding updates, ensuring long-term usability.

g. Market Research: Regularly monitor market trends, consumer preferences, and competitor packaging strategies to stay relevant and innovative.

Conclusion: Custom packaging boxes serve as a powerful tool for brand communication, protection, and differentiation. As a China Custom Packaging Box Manufacturer, mastering the art of custom packaging requires meticulous attention to classification, design, production, and adherence to important considerations. By combining creativity, functionality, and sustainability, your custom packaging can elevate your brand, enhance consumer experiences, and leave a lasting impact on the market.